Analyzing Machine Operation with Video

Several other posts have focused on the performance of human operators in a production environment. However video can also be used to better understand how

From my early work on transportation projects and wind tunnel sales globally, through founding iPOV (a video eLearning technology company), to recent projects in agricultural exports and supply chain standardization, I have operated in settings that required complex matching of scattered and disparate needs.

My 26-year academic career (mostly at Auburn University) provided a theoretical grounding in how complex systems function and fail, while my concurrent business ventures offered real-world lessons and earned skills and (mostly) validation of academic concepts. I researched everything from manufacturing quality standards to supply chain dynamics, learning patterns, and product variety management. My experience includes developing video-based training systems for manufacturers, creating innovative educational delivery platforms, and building technology solutions for complex operational challenges. This combination of rigorous academic analysis and practical business implementation inspired Cosolvent as a potential solution for automating the nuanced matching that these specialized situations require.

These posts are not directly related to Deeperpoint, but they illustrate some of the ideas and experiences that inspired it.

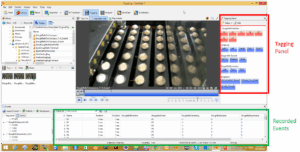

Several other posts have focused on the performance of human operators in a production environment. However video can also be used to better understand how

At the end of the Hartybake production process there is an automatic bagger. Waffles are placed on a conveyor with small moving pegs to control spacing. Workers transfer

In a previous post, I showed a way to extract detailed operational data from a video clip of human-paced operations. As I did the tagging,

A lot of customer service functions involve complex interactions between employees and customers. Studying and analyzing these interactions is complicated and time consuming. In the

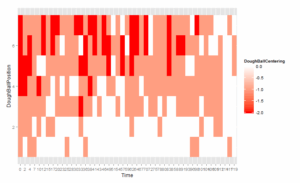

In a previous post, I described a novel way to use video to capture visual evidence of process variation and make it far more evident

A lot of process variation occurs over extended periods of time. You can see that something may be happening, but the quantity and nature of

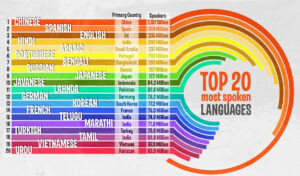

You have a critical procedure that must be followed across your global operation. You have vendors in China, plants in Portland and Valdosta, offices in