These timelines show Mustafa (Vic) Uzumeri’s professional journey. It began with early involvement in transportation planning in Canada, followed by a 7 year stint with one of the three companies in the world that you would call if you needed to build a wind tunnel. Then a PhD and 21 years teaching operations and supply chain at Auburn University, with a companion job as the founder of a boutique video e-Learning company that sold exclusively to Fortune 100 companies. Finally, early retirement and participation in a wide variety of projects and tasks, culminating in DeeperPoint.

I researched it … I wrote about it … I designed it … I did it … I led the company that did it … or I was a key member of the team that did it.

Origins

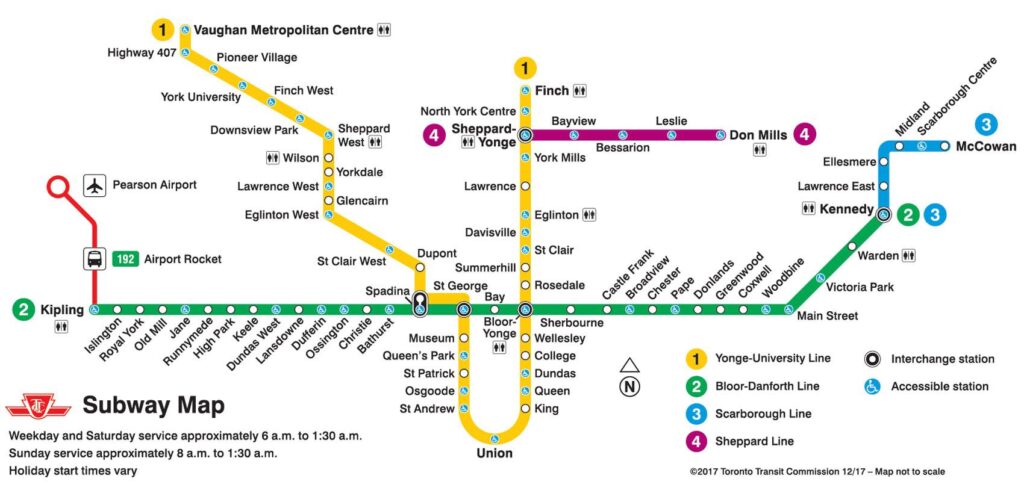

I got a job in the Research Group at Canadian Pacific Railways (CP) in Montreal. It was type of internal consulting group and we tackled whatever weird issue arose.

My biggest task was to rewrite the manual for cost-justifying capital projects at CP. In the process, I was schooled by the old-bull line managers that my MBA knowledge didn’t quite cut it for investments that were expected to stand for 100 years or more.

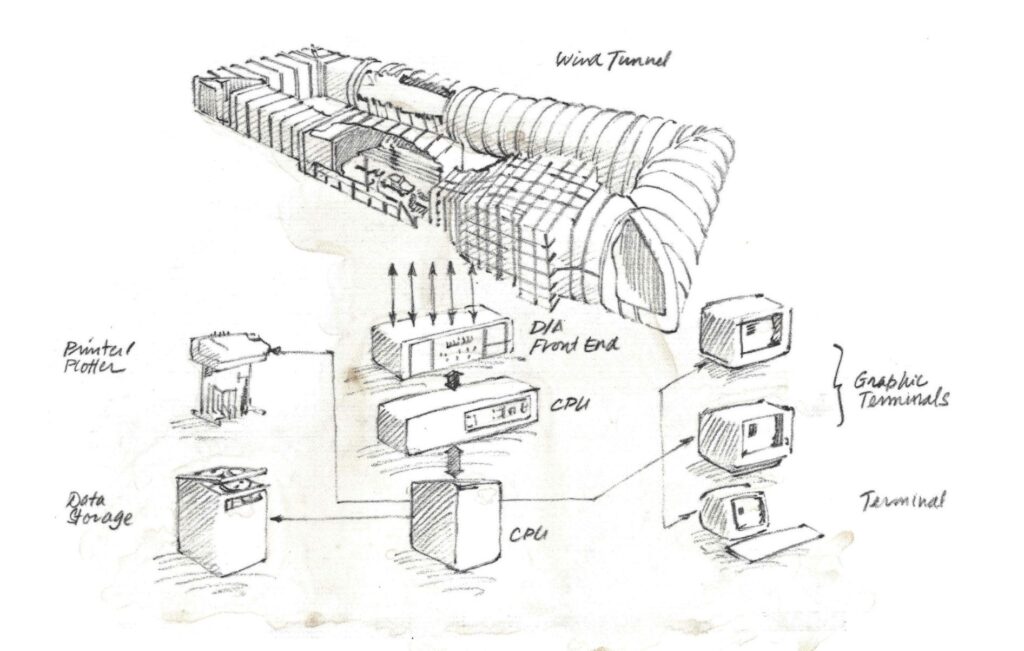

I was the liaison (i.e. shock absorber) between the management of an old-school engineering company and a group of crazy, but brilliant systems engineers. The geeks invented a system, “Talent” that was probably 5 to 10 years ahead of its time. It ran as a network of distributed physical and virtual machines … with real time performance that was absolutely insane.

I did the business development (i.e., made sales calls and wrote the sales proposals) for the systems and the technology.

They later formed a company (ReAct Technologies) that absorbed the founding firm … and is still the global go-to company for ultra-sophisticated research test automation systems.

Academic

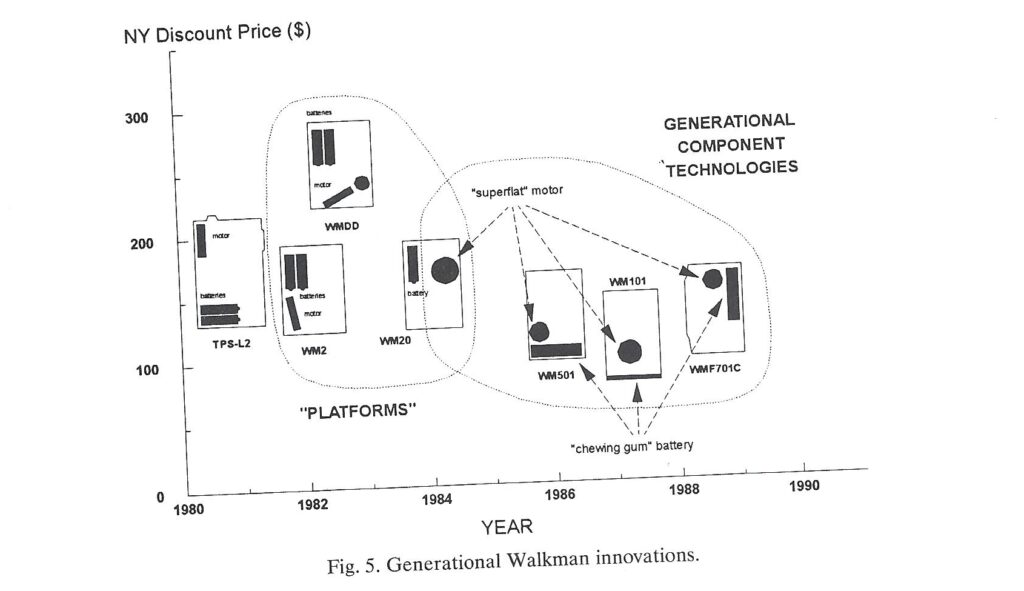

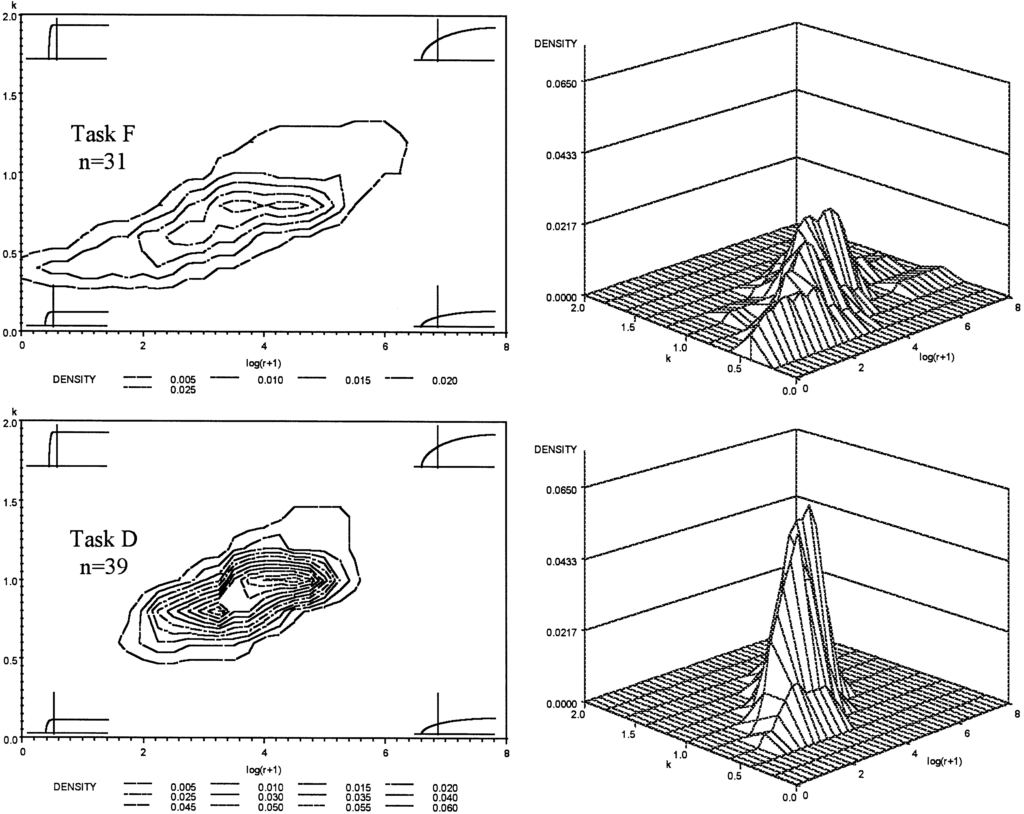

This was my PhD dissertation. I examined how product families differed on the characteristic of product variety and serial design change. I found a pattern that was stable and logical that applied across essentially all of the discrete products industries … at least at that time.

I was given access to corporate training data for an apparel manufacturer. There were records of thousands of employees who were learning how to sew t-shirts and similar garments.

David Nemhard and I developed a model of learning that modelled individual behavior as a stepping stone to modelling group behavior.

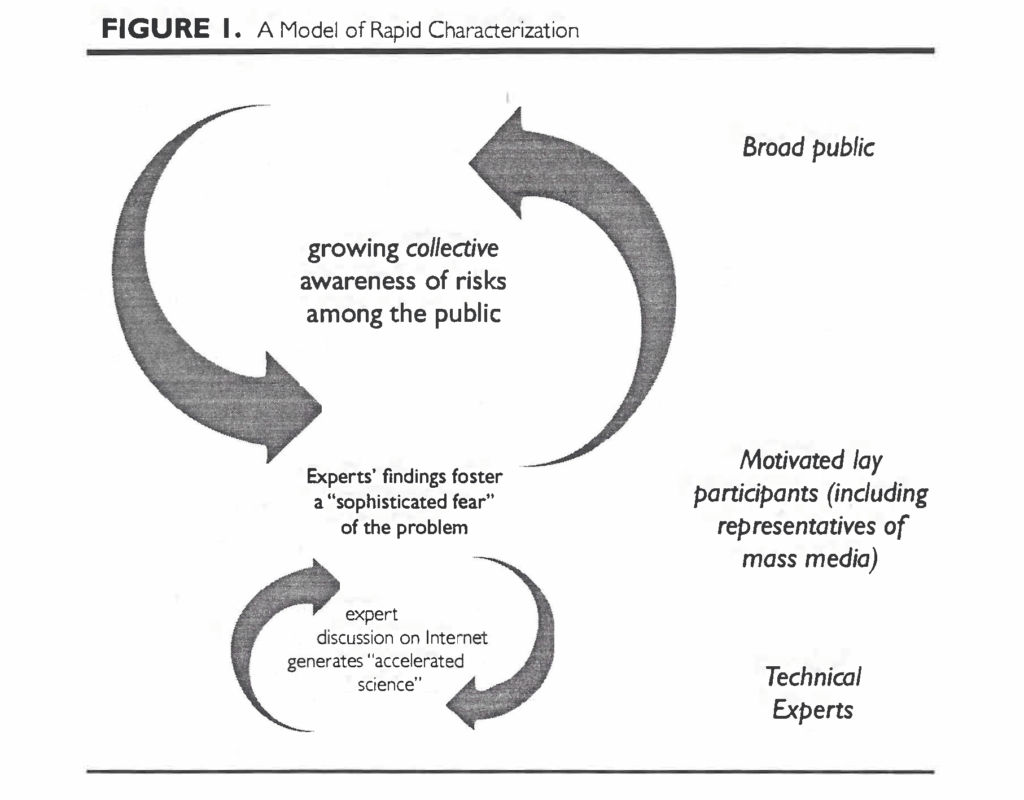

Intel made a mistake with its Pentium chip and a university researcher caught them out. The resulting furor ultimately forced Intel to recall existing chips at a cost of at least $250 million. I used usenet and Internet chat records to document the process. It was probably the first scholarly analysis of what is now called a “viral” Internet scandal.

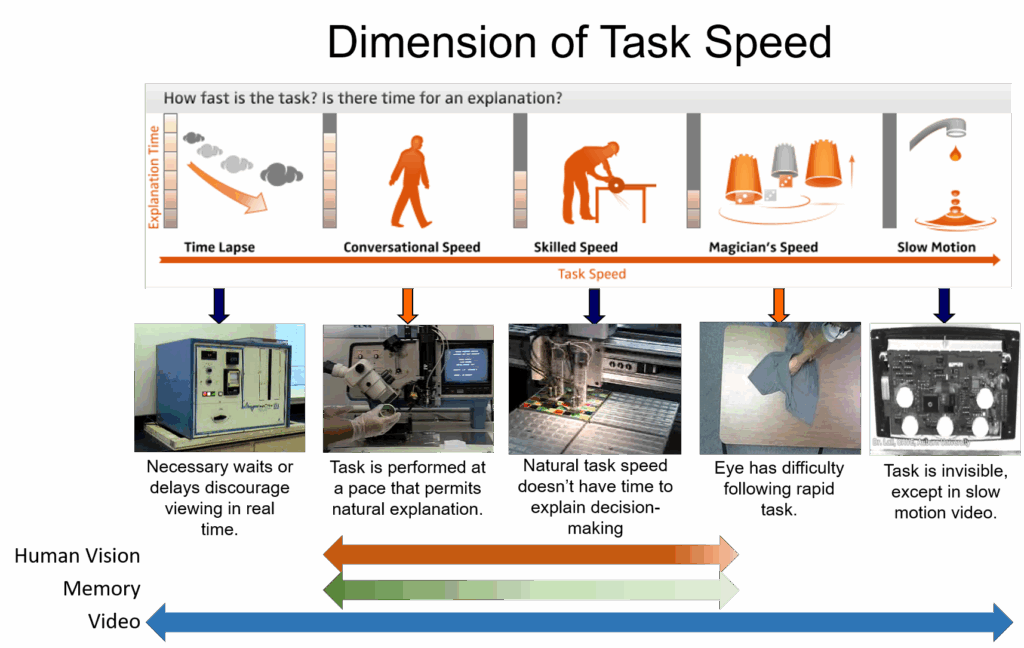

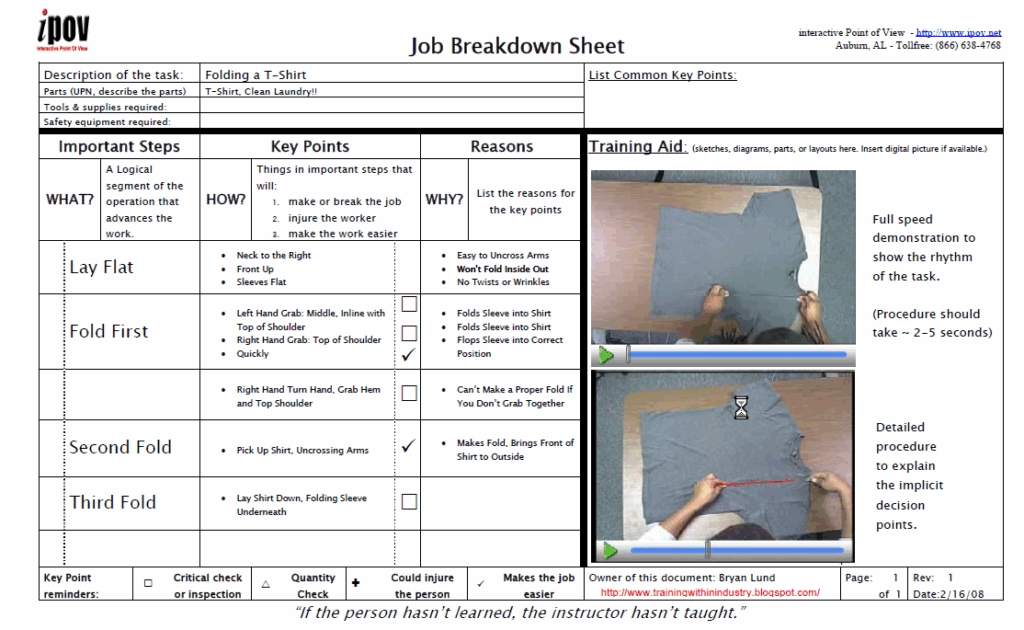

Chrysler’s Huntsville AL electronics plant spent nearly 2 years investigating and evaluating how to apply cutting edge video editing tools to the production of plant floor training materials. The original technology came from Quantel … a global broadcast video vendor.

Although Chrysler ultimately declined to move forward, this project set me off on a 25 year quest to understand how video can be used in day-to-day business operations.

In the late 80’s manufacturing companies around the world faced demands to adopt a manufacturing quality standard: ISO-9001 … then endure audits to certify they conformed.

I was fascinated because academic theory said that management practice cannot be standardized. Yet thousands and eventually millions of companies complied. Either management theorists were wrong or the standards writers were using smoke and mirrors.

I spent 7 or 8 years digging into the phenomenon to try to resolve the contradiction. I think I succeeded because I wrote 4 or 5 journal articles that were accepted at good publications.

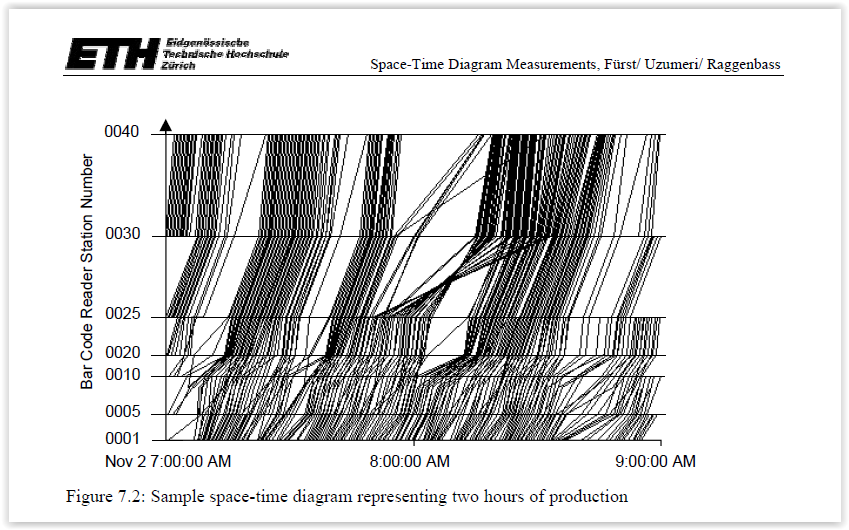

I had several German students visit Auburn to study with me. Alex, Steffi and Fabian. Not sure why I was chosen, but they were great kids and all went on to good things. Fabian took an interest of mine and developed it into a Master’s thesis that was very thorough and coherent. It sliced and diced the concept of space-time diagrams as they applied to production and similar operations.

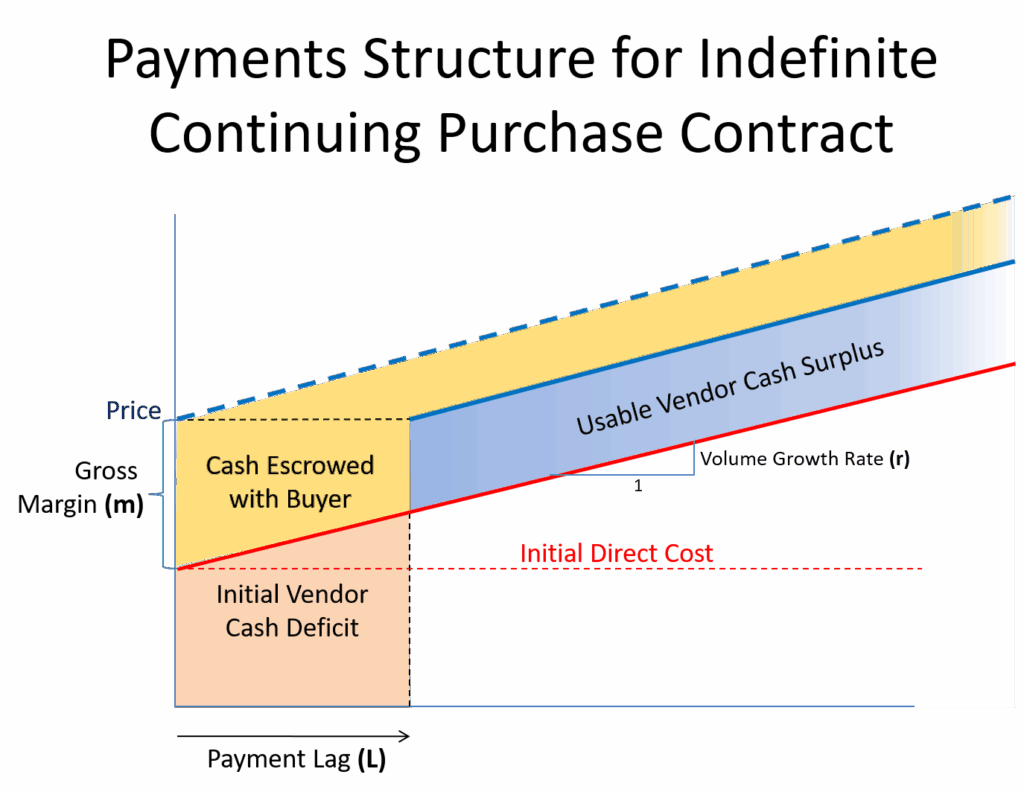

Since iPOV was always eagerly waiting for payments from big customers, I became interested in the implications of steadily lengthening payment terms.

I ended up with a surprisingly simple model that largely upended all of the stuff we were teaching MBA students.

Even before we moved to Atlanta, I was fascinated with the idea of using mobile networks to teach. Universities had been teaching remotely for years and I taught for 6 years in Auburn’s Executive MBA. But on-campus students desperately need to see the reality of the outside world … and it is very hard to bring that back to campus. The occasional guest speaker doesn’t really cut it.

By 2012, the technology pieces fell into the puzzle. I hopped around Atlanta with a laptop, a webcam and Verizon 4G. I delivered live lectures from the floor of a shipping dock, from a trade show floor, from the offices of Home Depot and Chick-fil-A logistics executives. Reality baby! I will probably write several articles about the concept and my experiences with it.

iPOV

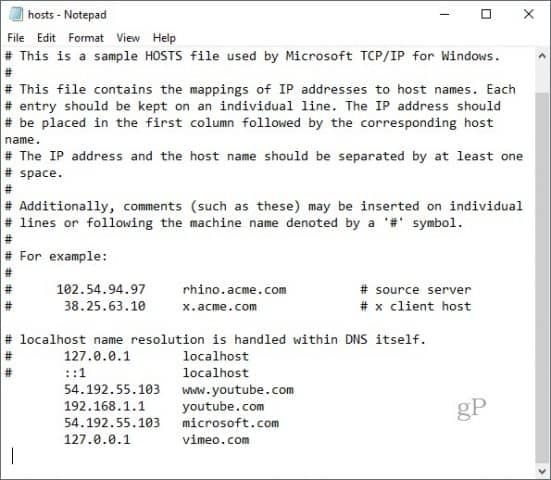

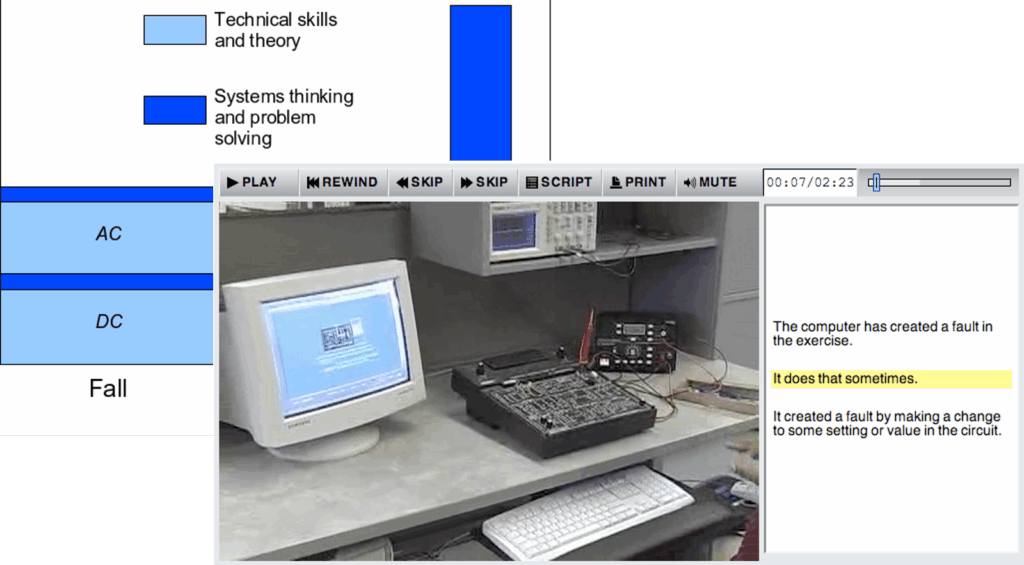

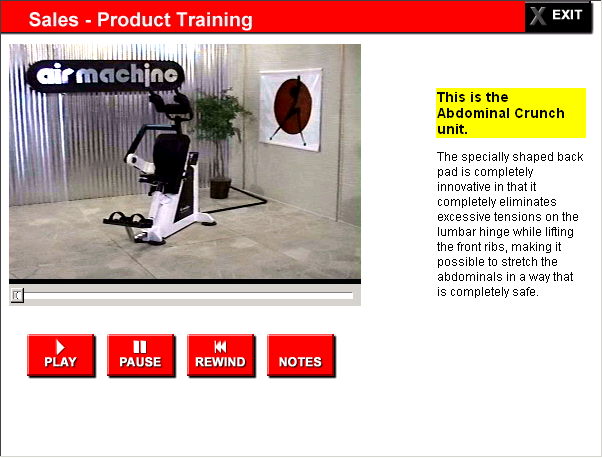

Over a 10 year period, iPOV developed a collection of cool web software tools for eLearning. Technologies included Flash Actionscript, XML, and video. Some of our best stuff used Flash to put dynamic, interactive layers over standard video. That wasn’t really replicated in web video for at least a decade.

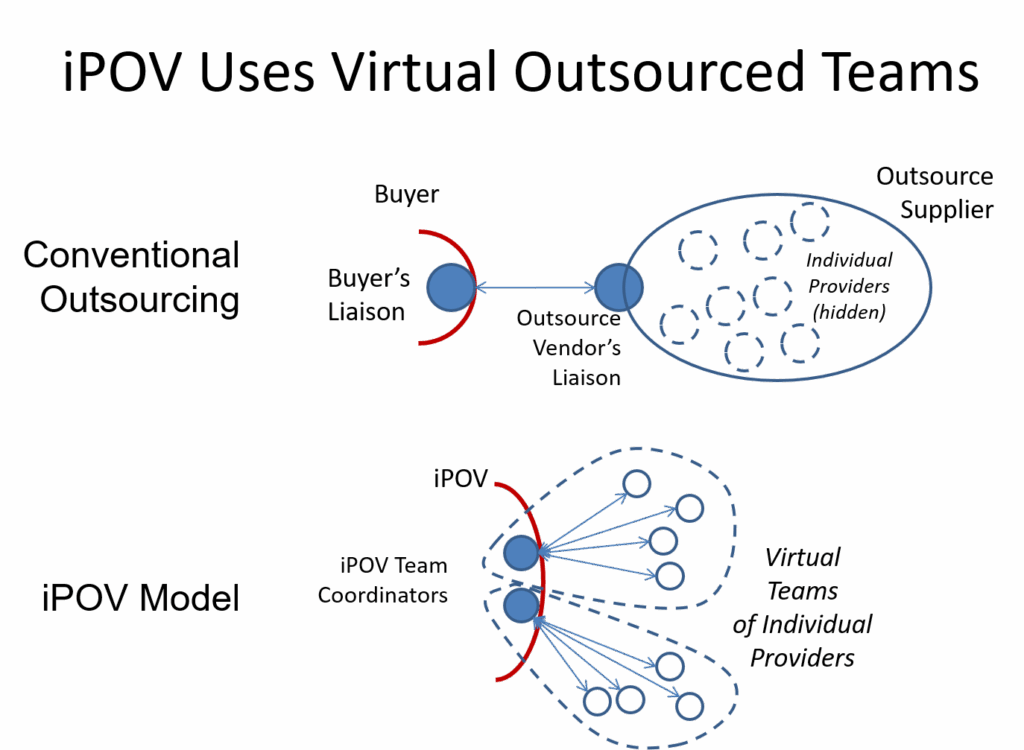

For a decade iPOV relied on work by part-time Auburn students. They so consistently exceeded expectations that most ended up in great jobs after graduation. Many of them credited the opportunities and mentoring they received at iPOV. From this experience, I evangelized for the concept that universities could support an ecosystem of “farm team” companies for large employers. No one seemed interested, but I am still convinced it is an excellent and practical idea.

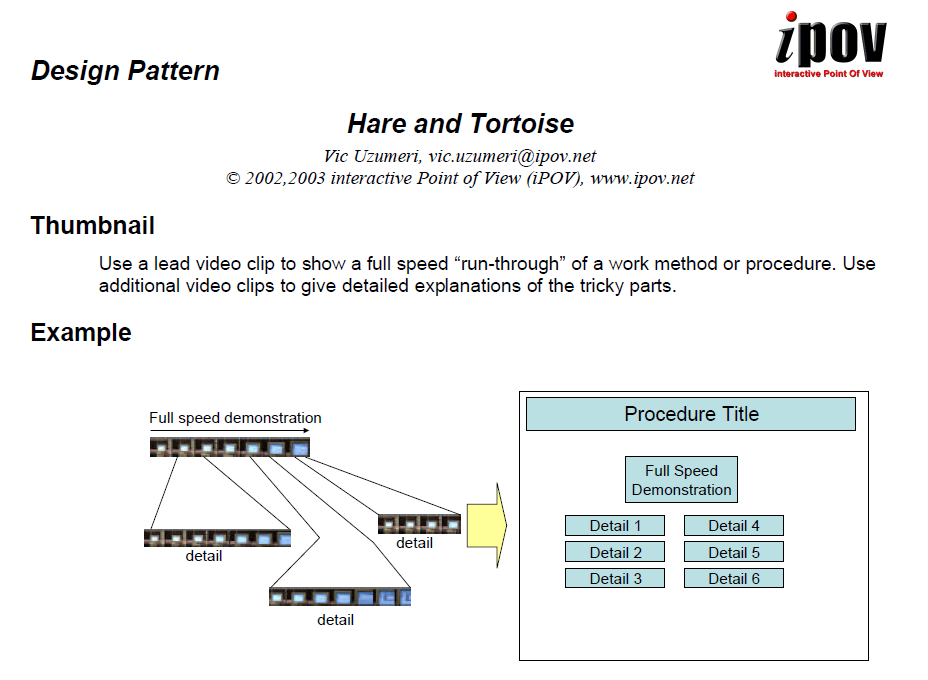

One of iPOV’s secret weapons was a system of simple design patterns for eLearning. They were not so much designed to look good … although they could. They were designed to make it easy and foolproof to build material that was clear and accurate. We never really got our clients to grasp that point, which is too bad, but it really helped us cut costs.

iPOV developed a “youtube clone” based on open source software. It was designed to make searching video much easier and faster … easier even than Youtube. It worked, and we used it extensively in our projects, but the death of Flash killed it too … even though we had switched everything to mp4, it was too late.

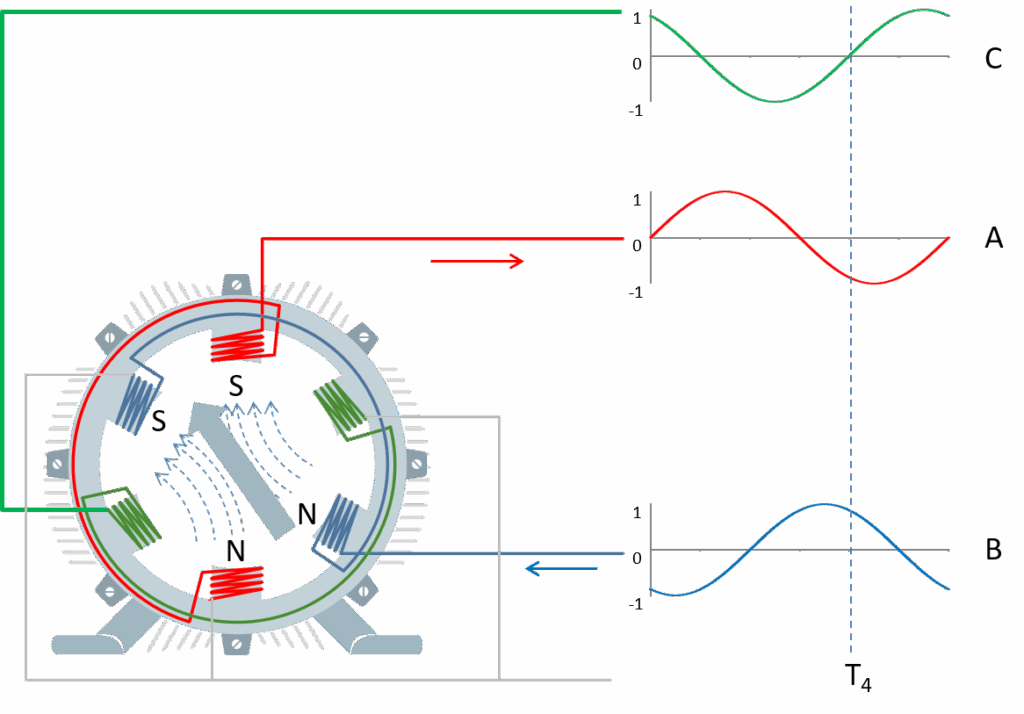

AC Motors are incredibly common and important. They are also amazingly simple and elegant, thanks to Nicola Tesla. However, it is no easy chore to explain them to non-engineers. I tried this for Siemens and I think I came pretty close to nailing it. This was the first project where I tried to use simplified visual models to explain a mysterious and obscure system.

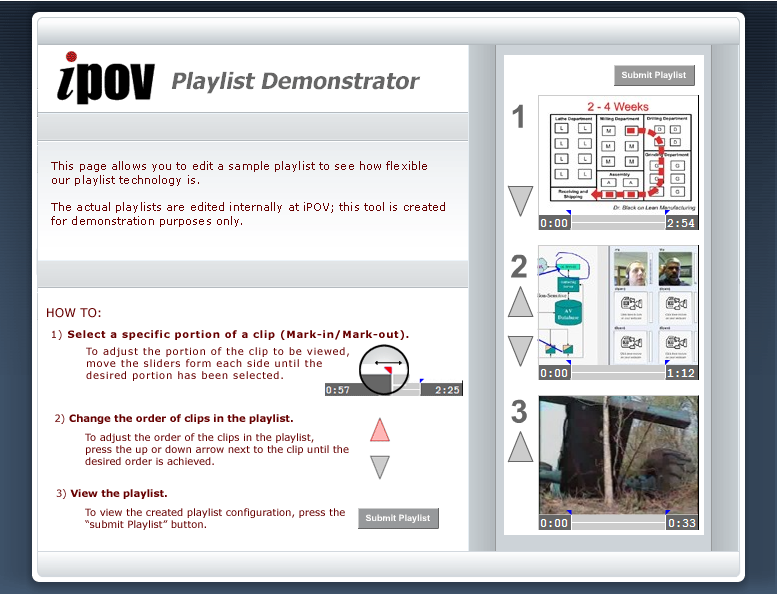

iPOV took Flash to its logical conclusion by creating a web video player that could be actively reprogrammed on the fly. We used it a lot ourselves, but we never really got traction trying to offer it to others. Poor marketing was a big part of that, but the growing resistance to Flash played a part. Eventually, we gave it away as open source.

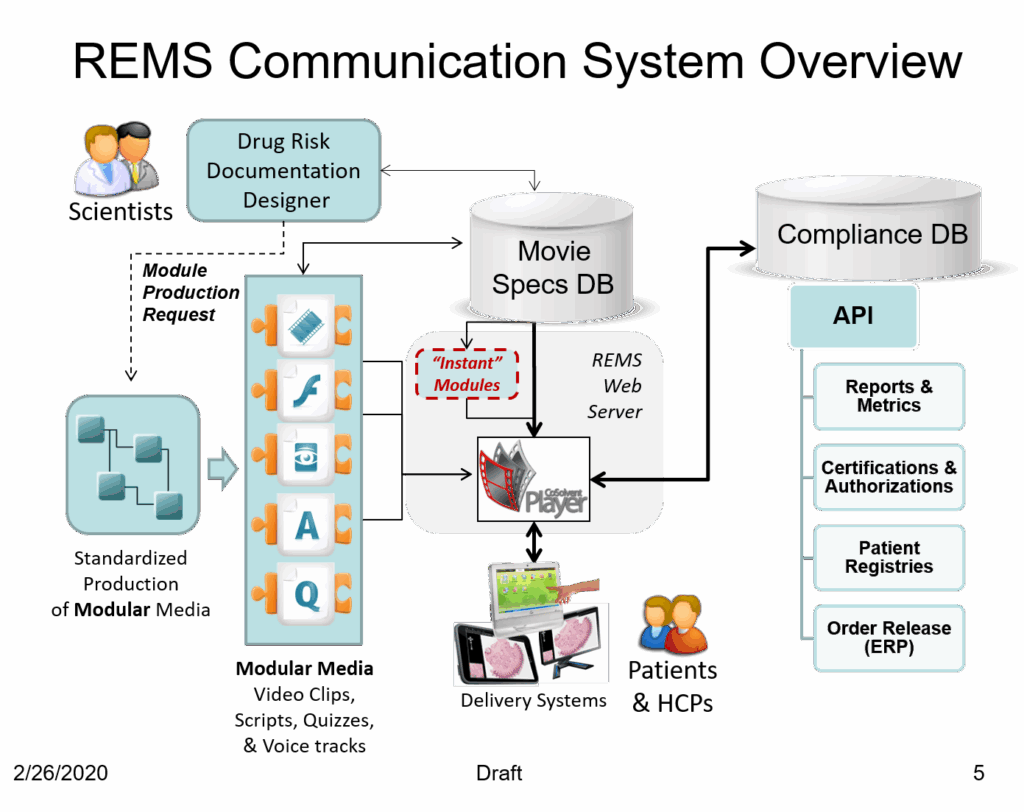

iPOV’s love affair with Flash hit a peak when we were asked to propose a system to Amgen. They didn’t buy it, but the design was awesome … and we had all the pieces already working. The system would have interactively edited video snippets into polished sequences, depending on the preferences indicated by the viewer. Instead of watching a long training video with a lot irrelevant parts, you would see just exactly what you needed to see.

Steve Jobs might as well have blown up iPOV’s offices. He announced that Flash would not be allowed on the iPAD and all of our corporate customers started to demand we deliver materials without Flash. We had a ton of features that could not be replicated with mp4, HTML5 and javascript. Arguably, they weren’t replicated for nearly a decade. I learned a lot in the next few years of hopeless fight.

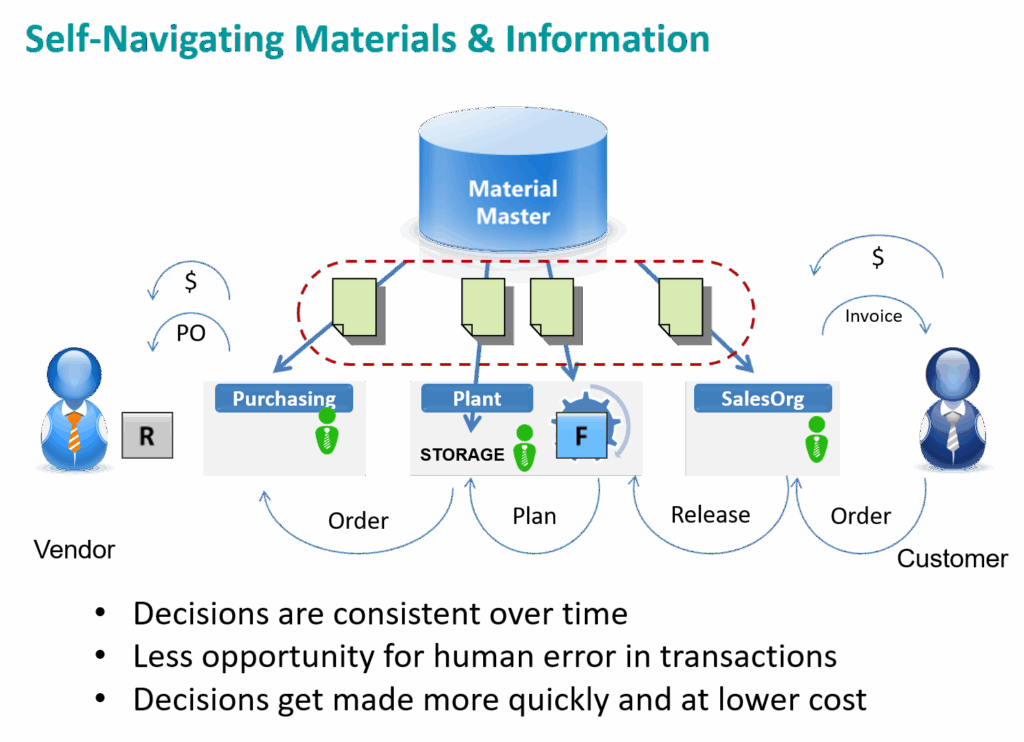

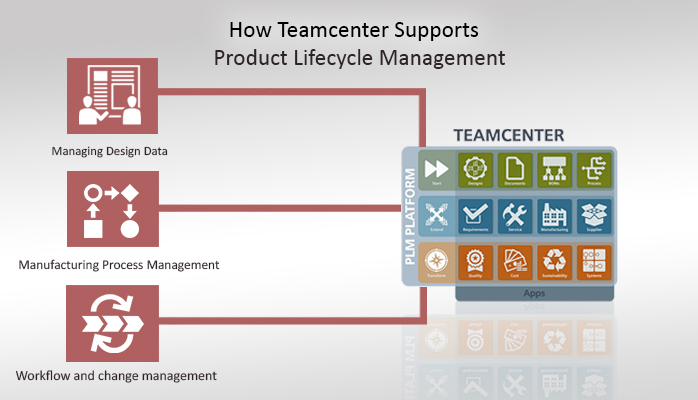

The idea of a “material master” is central to the design of every major class of transaction management software: CRM, ERP, WMS, Payables, etc. Like AC motors, however, it is usually perceived as a mystery that most employees don’t want to try to understand. iPOV came up with a pretty elegant, animated explanation.

Recent

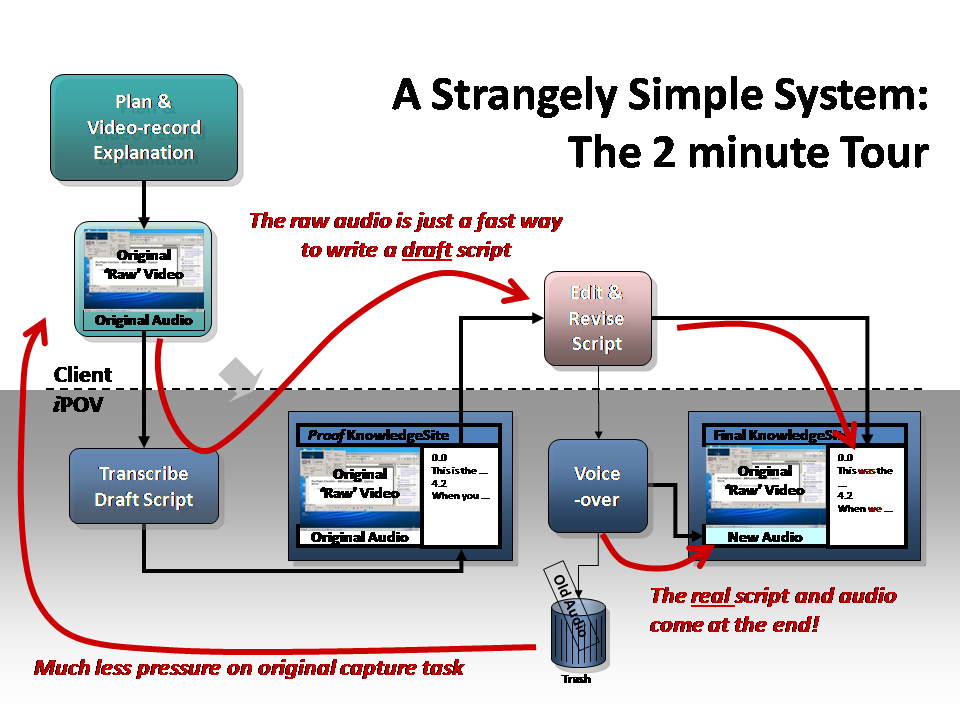

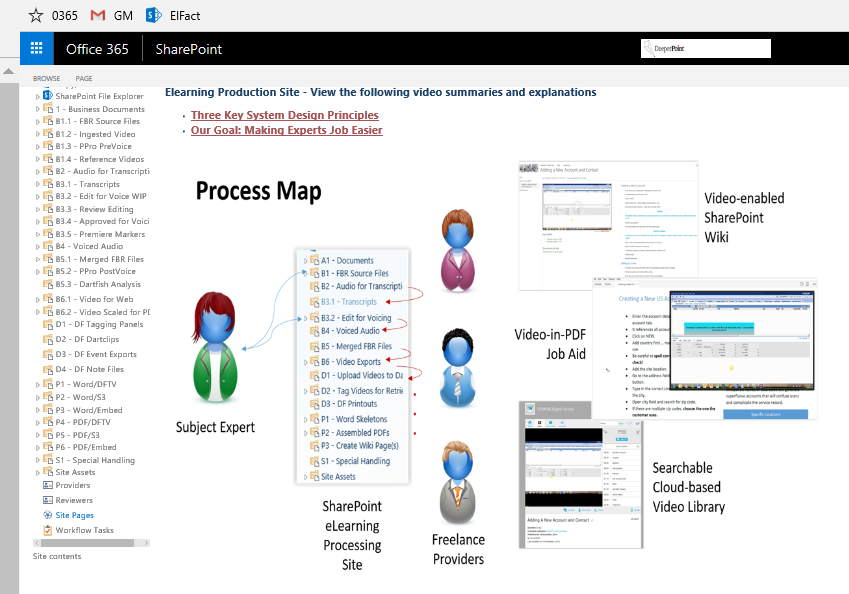

When I shut down the Auburn iPOV operation, I had to invent a new eLearning production process that would work with remote freelancers. To make the system more appealing to corporate clients, I set it up to use Adobe Creative Suite and Microsoft SharePoint. With the advances that have occurred in both sets of tools, it actually works pretty well.

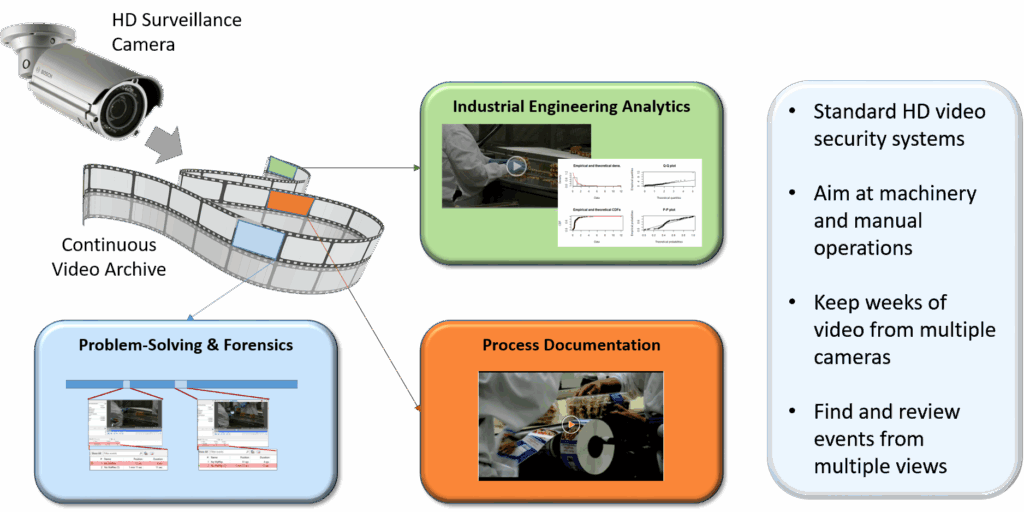

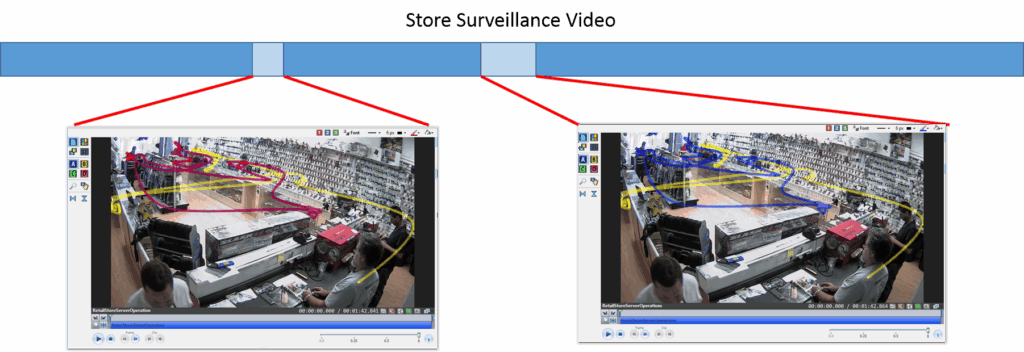

I worked with an industrial bakery, Dartfish and Michael Darden to explore a variety of ways to use video to capture raw data for operations analysis. This didn’t really lead to any dramatic opportunities, but it offered tremendous promise and was very interesting.

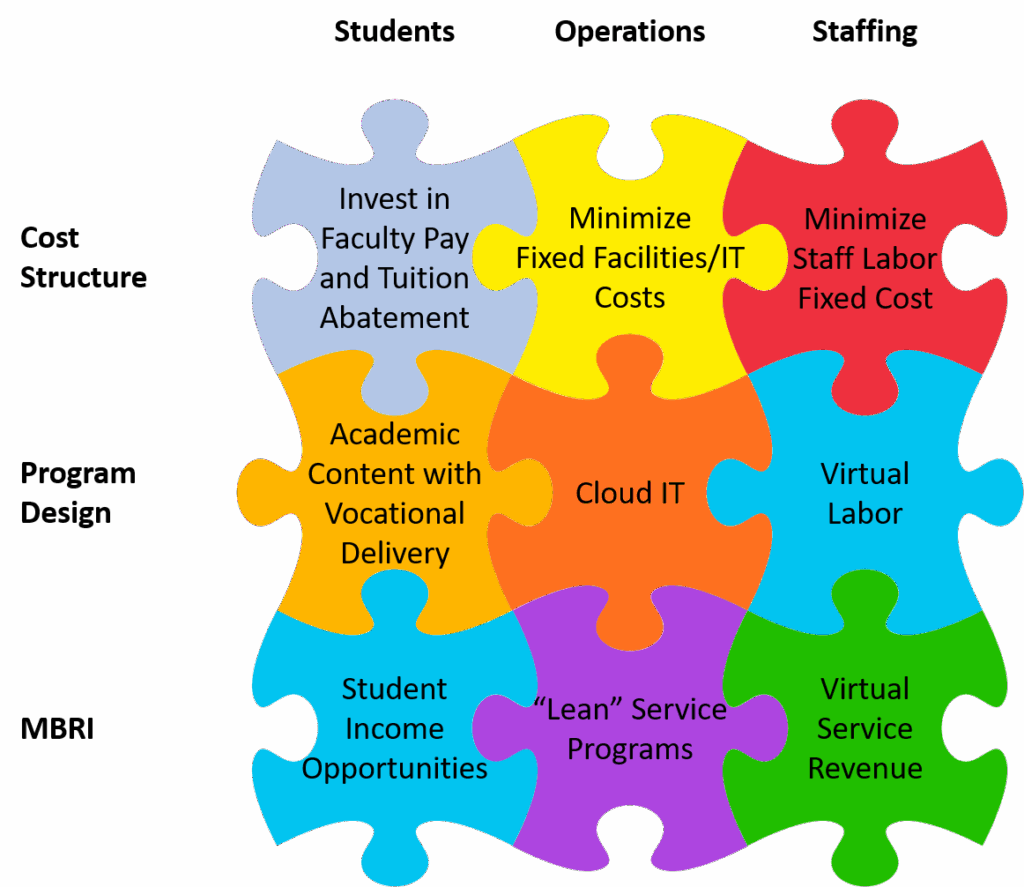

I was briefly drawn into the efforts of Morris Brown College to resurrect itself from oblivion. Their situation was dire, so I tried to think outside the box and find a teaching model that could work at much lower cost. Nothing came of it, but the exercise gave me some insights and ideas.

I hope to write a series of articles based on this exercise. My idea is to restructure Higher Ed so it stays true to its heritage, but uses new business tools to “manage” how they teach the traditional subjects.

Let’s eliminate the ridiculous idea where schools waste time teaching courses in “Microsoft Word” or “Project Management”. Those aren’t worth courses … just use them as the tools you use all the time to teach real topics like psychology, business, design, etc.

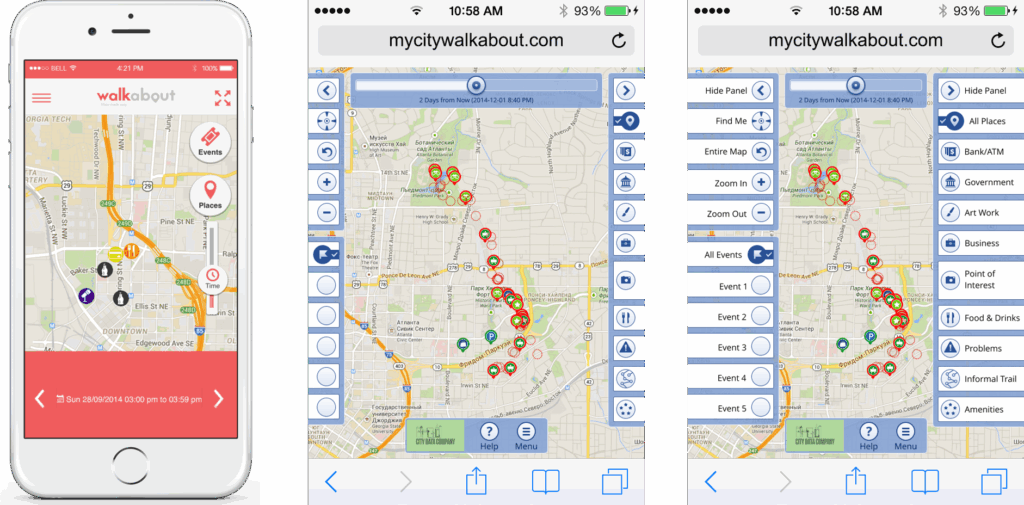

For about a year, I wrangled the team of developers (in Algeria and Mexico) to create a flexible event mapping utility. It was totally responsive so it ran on desktops and mobile. It also fed anonymous data back to a database where we could build maps of visitor behavior.

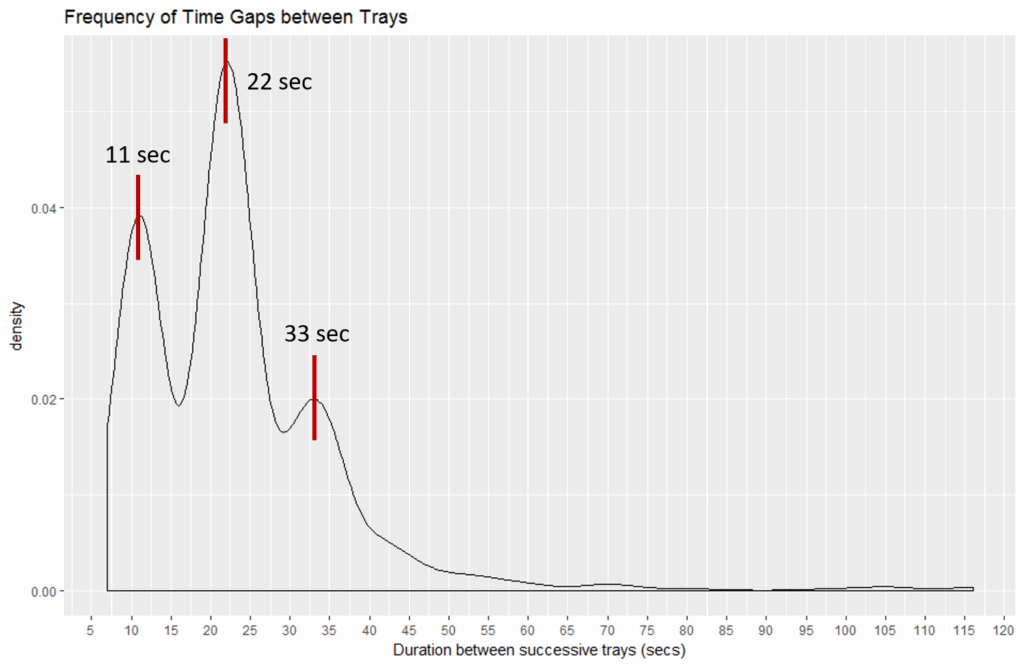

A friend owns an industrial bakery. I talked him into installing some surveillance cameras and a decently capable video management system to observe operations … particularly in his production machinery. A lot of weird things can happen with waffle and pretzel dough and there isn’t always a person nearby to see it.

I worked with a local industrial bakery to integrate IoT sensors into their suite of surveillance video. The idea was to recognize machine events from the factory floor and use that data to make it easier to find relevant video on the surveillance system. The project petered out for reasons unrelated to the technology … but I was able to assemble an effective proof of concept before things wound down.

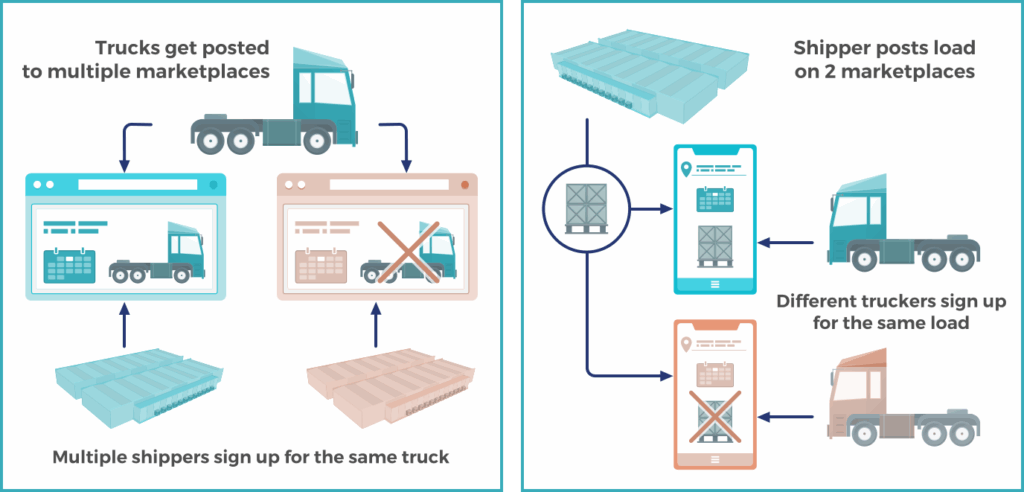

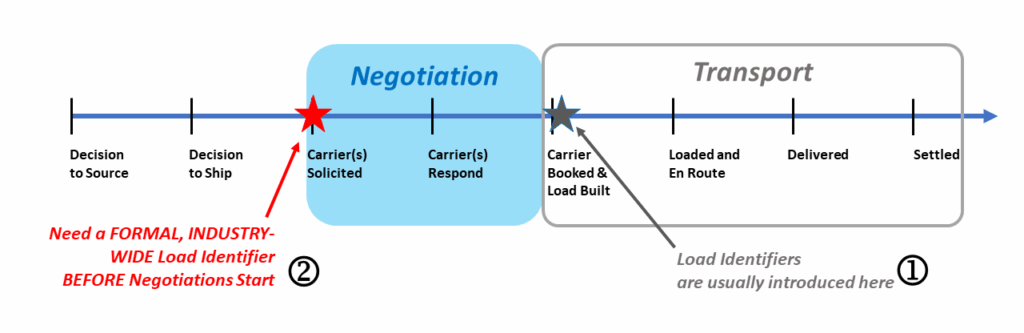

I resumed work with Michael Darden and DFM Data Corp. in a supportive role. DFMDC is tackling a hugely important problem that is beginning to surface in the US trucking spot market. The spot market arranges 500,000 to 1.5 million truck loads per day. It’s not an exaggeration to say that a major disruption of this market would cause havoc in North American logistics. Michael asked me to look into the mechanics required to clean “phantom data” from the growing DFM ecosystem. DFMDC, through Michael, owns an active Patent that covers this activity along with many other aspects of the DFM process. My investigation resulted in two findings: a) the problem is real and big, and b) the way the DFM industry works, it is really hard to fix unless we can institute a reliable ID on planned truckloads before they enter the negotiation and bidding system.

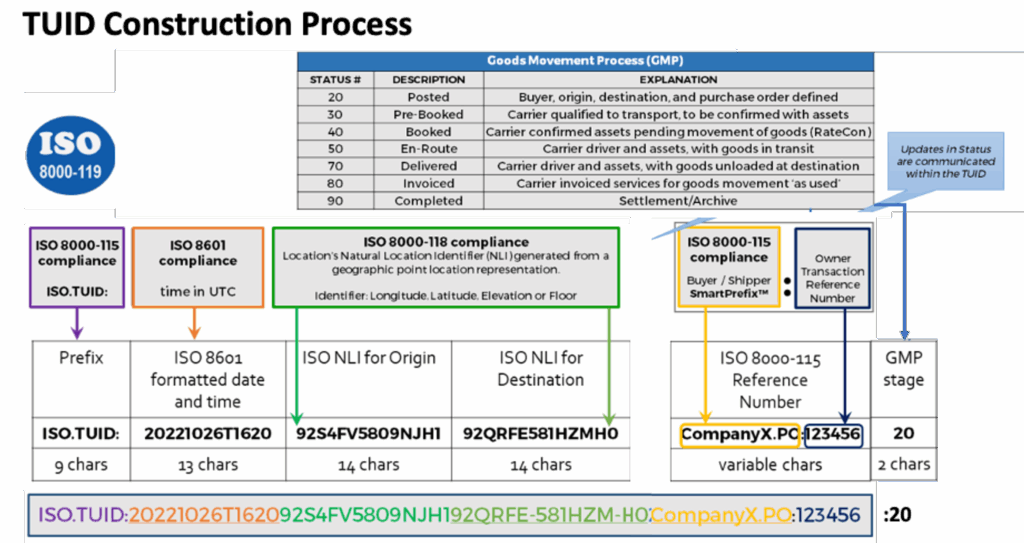

My previous investigations into the problem of trucking “phantom data” led to a proposal for an industry-standard Transport Unit ID (TUID). As a conversation starter, I proposed a simple method by which any shipper could create an ID that was extremely unlikely to conflict with those created by other shippers. The TUID idea, in turn, has led to many interesting possibilities to improve cooperation and interoperability among trucking industry stakeholders.

In the aftermath of the Pandemic, global supply chain stakeholders have been doing a deep re-evaluation of SC structure, performance and transparency. In a prior exercise, I wrote a couple of white papers about the need to institute a common unique identifier system for North American trucking. Michael Darden and others picked up on that and linked the concept to standardization initiatives for supply chains on a global basis. I have since joined their work in working groups for ISO 8000-119 and ASTM F49.01. The former has proposed a format for a global Transport Unit ID (TUID) that can uniquely identify any shipment, anywhere in the world. Even better, the 8000-119 TUID can be self-generated by the parties to the shipment. It would be helpful if there is a central dispensing service, but it is not strictly necessary. This makes it a very non-threatening standardization option. The ASTM F49 effort aims to develop a standard lexicon and vocabulary for Supply Chain Operations that is capable of being applied across all modes, even worldwide. In both cases, I am actively involved in larger team efforts.

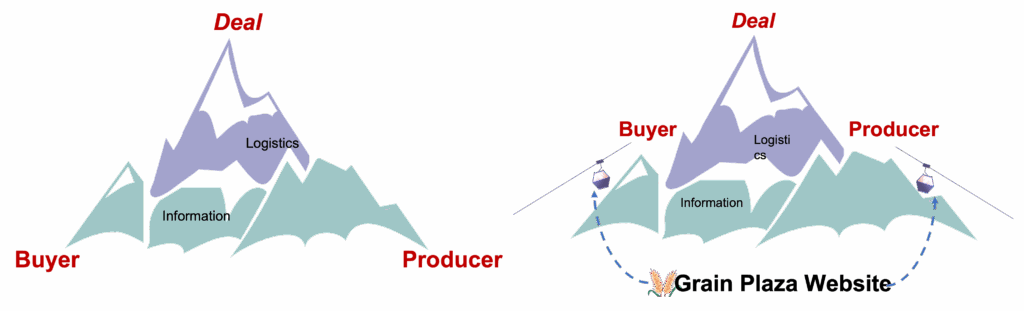

Canadian prairie grain producers have been exporting their crops (wheat, corn, barley, peas, soybeans, etc. etc.) around the world for many decades. However, in an increasingly competitive and global economy, the system is still focused on selling and shipping bulk quantities … trainloads and shiploads. Even though Canada grows some of the highest quality grains in the world, Canadian farmers often get the commodity price rather than the premium price that their crops deserve.

I am working with a long-time colleague on an idea to change that. The goal is to build a website that is designed to showcase Canadian producers and Canadian crops in a way that a distant buyer will have enough information to risk contacting and working with the Canadian producer. It has some similarities to the concept behind AliBaba, but with many differences that reflect the specifics of an agricultural crop.

The initiative for selling prairie grains morphed into a focus on developing an AI-enhanced system to match remote and arms-length business interests. A system like this might consummate the deal, but it could plausibly help the parties to speed through the mating dance to decide if they want to finish up offline.